Reactive silencers are intended to attenuate low frequency noise – up to 60 dBA attenuation

Reactive silencers are used to attenuate low frequency octave band noise – up to attenuation of 60 dB (A)- produced by the exhaust of rotating machines such as diesel / gas engines, compressors, pumps …

Reactive silencers reduce noise pollution from exhausts. They are found on a wide variety of industrial sites.

Since several decades, with a large reference list in all countries and among major international companies providing an unrivaled experience in the domain, SAI acquired a complete master in the design, fabrication and installation of such equipment.

Acoustic and mechanical dimensions following the international norms are optimized to reach the contractual performance in the safest conditions.

Proven design in various conditions

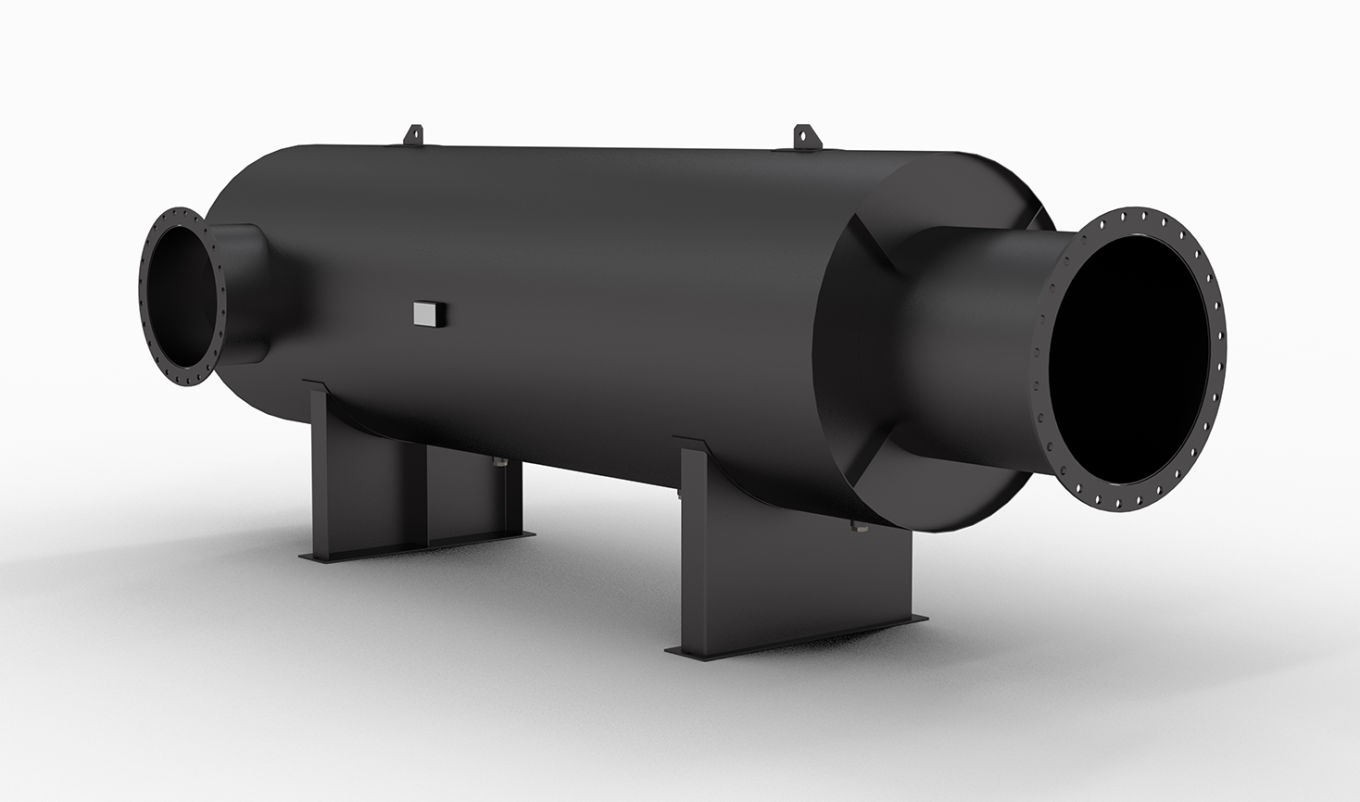

The shape of reactive silencers is usually cylindrical. These silencers include several gas expansion chambers communicating via impedance tubes. The length of the tubes depends on the frequency of the rotating machine and the harmonic frequencies.

The length of the tubes and the number of chambers are calculated by proprietary software providing satisfactory performance as proven with our reference list.

An additional stage with acoustic absorbent can be added to obtain the proper noise attenuation.

An additional stage with acoustic absorbent can be added to obtain the proper noise attenuation.

With its proven technology, SAI is able to design equipment with extreme process conditions. As example: steam/gas flow rate up to 500 tons per hour, temperature up to 500°C with a pressure at entry reaching 200 bars.

An optimized design

To reach the expected performances, the design of an absorption silence requires the knowledge of additional parameters depending on the process. Among them:

- Type of gas: air, smoke …

- Mass flow rate (Kg/s …)

- Inlet temperature (°C, °F …)

- Machine characteristics (number of cylinders, rpm …)

- Acoustic performance Lp at 1m (dBA)

- Pressure at entry per frequency octave band without silencer

- Maximum pressure drop acceptable.

Robust fabrication with available options

Depending on the installation of the silencers in its environment, different options related to the design or to the fabrication are available to meet the needs of the customer. As examples:

- Flanges or butt weld at inlet

- Vertical or horizontal installation

- Rain cover or round elbow

- Protective mesh

- Special paint

- Carbon steel S235JR or P265GH or corten or alloy / stainless steel 304, 316, 321

- Sparks arrestor

- Calculation notes considering site conditions (wind, seism…)

- ITP or Manufacturing Quality Plan with customer inspection if required