Through its very rich experience acquired with operators on all continents, and through the multitude of situations encountered during all phases of a project, SAI can provide studies to define and dimension acoustic solutions.

For more than 40 years, SAI has acquired a unique knowledge thanks to many achievements in both noise and air treatment. SAI’s engineers can therefore understand and master complex problematics.

Whether it’s for remedial or preventive actions, SAI offers personalized solutions with guaranteed performance in acoustics, aeraulics, mechanics, etc.

The engineering and design phase are the basis for good project implemention. In order to define the design of a specific project, our specialists use measurements, simulations, calculations or analogies to previous projects. Their objective is to optimize performance and also to comply with various requirements and standards. SAI’s designs always take into account the costs of manufacturing, packaging, transportation, erection, maintenance access, security, etc.

Acoustic and sound analysis becomes mandatory and essential when in compliance with standards such as ANSI, DIN, IEC, ISO as well as Environmental, Health and Safety (EHS) Directives. It is also necessary in the event of ICPE classification (Classified Installation for Environmental Protection).

Acoustic diagnosis and measurements

In the case of on-site expertise, SAI uses several measurement tools:

- Sound intensity systems, to measure the sound power of equipment in its environment, in accordance with ISO 9614.

- Acoustic cameras which use the latest beamforming technologies. When identification of acoustic weaknesses or leaks is complicated, in the presence of a large number of sources, acoustic cameras allow us to isolate the predominant frequency bands and proceed with further remedial analysis.

- Class 1 sound level meters, enabling to measure sound pressure levels. These measurements are generally used to characterize the noise of industrial equipment, to analyse the compliance of industrial sites or to serve as input data to carry out environmental acoustic impact studies or any type of pre-project acoustic study.

Measurement equipment is regularly calibrated and verified in laboratories in order to ensure their compliance with ISO 9001.

As part of a pre-design study, SAI will use its experience based on its very rich database and goes beyond the data indicated in customer specifications. SAI is equipped with the latest calculation tools developed to calculate and design: hoods, acoustic enclosures, anti-noise acoustic screens, dissipative or reactive acoustic silencers, etc.

Acoustic studies

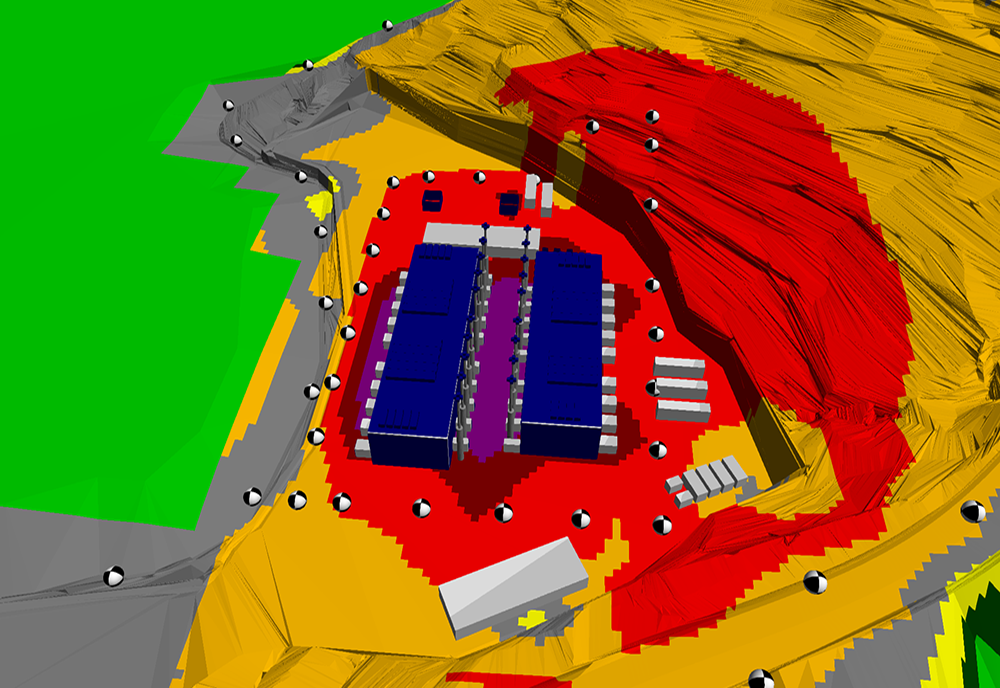

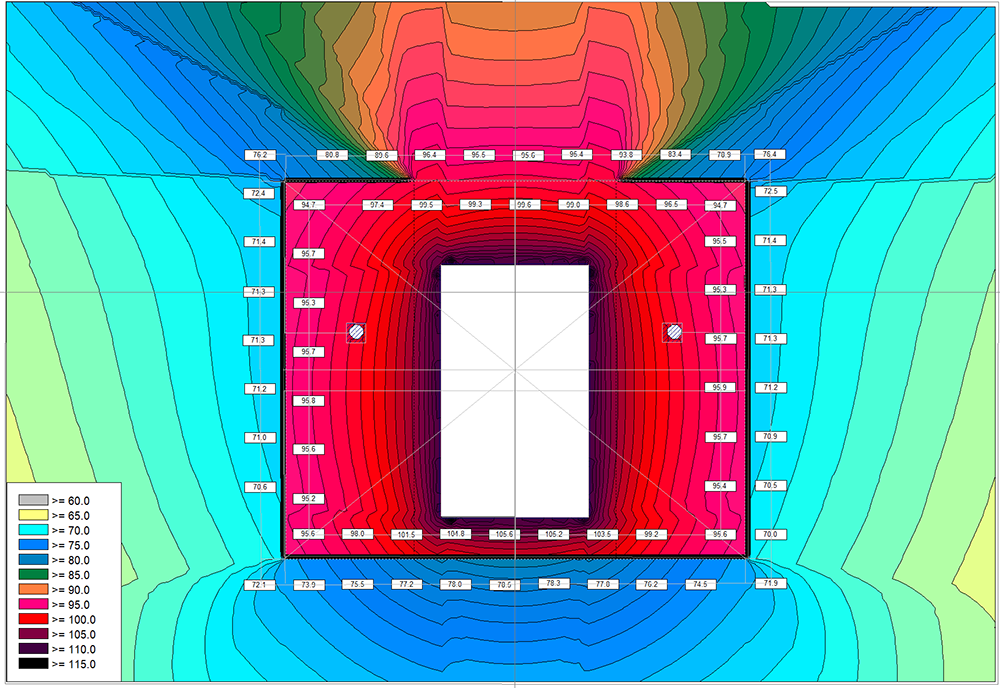

SAI masters powerful software that can predict the sound pressure level according to the source, place and environment. Studies are in fact necessary to guarantee the required acoustic level.

The acoustic mapping, in accordance with ISO 9613, and the analysis results lead to the identification of the predominant noise source among others and thus allow us to provide the most accurate solutions and at reduced cost.

Acoustic mapping takes into account all sources located on industrial sites. This may concern:

- Diesel engines, gas turbines

- Exhausts

- Combustion air intakes

- Compressors

- Ventilation system

- Air coolers

- Gas heaters, piping

- Transformers etc

Acoustic radiation from building facades, roofs and doors are also taken into account in 3D modeling, as they can turn out to be a significant source of noise.

As the challenge may change from one project to another, SAI is able to adapt to the client’s needs and can provide consultancy services on general acoustic targets or criteria to be reached.

These criteria include compliance with sound levels such as:

- Lp <85 dB (A) 1 m from the equipment for an exposure period of 8 hours a day

- Lp <55 dB (A) at the property line during the daytime (7 am-10pm) for residential areas, and Lp <45 dB (A) during the nighttime period (10 pm-7am)

- Maximum allowed difference between residual noise without equipment and ambient noise in the presence of equipment : + 3dB(A)

Factory tests and procedures

SAI sets prototypes that allow testing real acoustic performances for supplied scope such as enclosures, acoustic materials and ventilation systems, etc.

Certificates of conformity can be issued, and tests are carried out in the presence or absence of third-party organizations or inspectors.

SAI also provides reports with recommendations to comply with acoustic performances regarding environmental standards and laws.