Infrared Anti-Icing

For over 15 years, SAI has been a world leader in supplying bleed heating anti-icing nozzles used in air intake systems for gas turbines. In addition, SAI has developed a range of infrared anti-icing emitters also suitable for gas turbine combustion air intake systems.

One main cause of static filter failure in cold climate is the formation of frost. Depending on the weather conditions such as temperature versus relative humidity, frost then ice on the air filters will lead to reduce the airflow. At some point, the equipment is not able to operate in satisfactory conditions and is stopped.

For gas turbine combustion air intake systems, two solutions are used:

- Air heating with batteries

- Air heating by injection of warm air

In both solutions, the intake air is heated by a few degrees to avoid frost conditions.However, a warm intake air reduces the efficiency of a turbine. In addition, the use of batteries creates more important pressure drop. By heating the intake air, the loss of efficiency is significant up to 8%

Infrared anti-icing principles

Despite a small electrical consumption, the infrared anti-icing by SAI has several benefits maintaining the efficiency of the turbines even in winter conditions: no significant temperature increase of intake air, no pressure drop and very limited installation space.

Infrared anti-icing system is arranged in banks of emitters equally spaced to get a full coverage upstream the filter surface. In nominal operation, anti-icing is used with a temperature from -5°C to +5°C and a relative humidity above 70%. Based on radiation principle, intake air is not directly heated. The main part of the heating power is transferred to the filtering elements and to the water drops in the airflow. Therefore, the distance between emitters and filters is essential for the efficiency of the system.

A proven technology developed by SAI

Since many years, SAI has developed an important installed base of air intake system for gas turbines, thermal engines and compressors. SAI has a unique experience to install infrared anti-icing solutions in air intake systems.

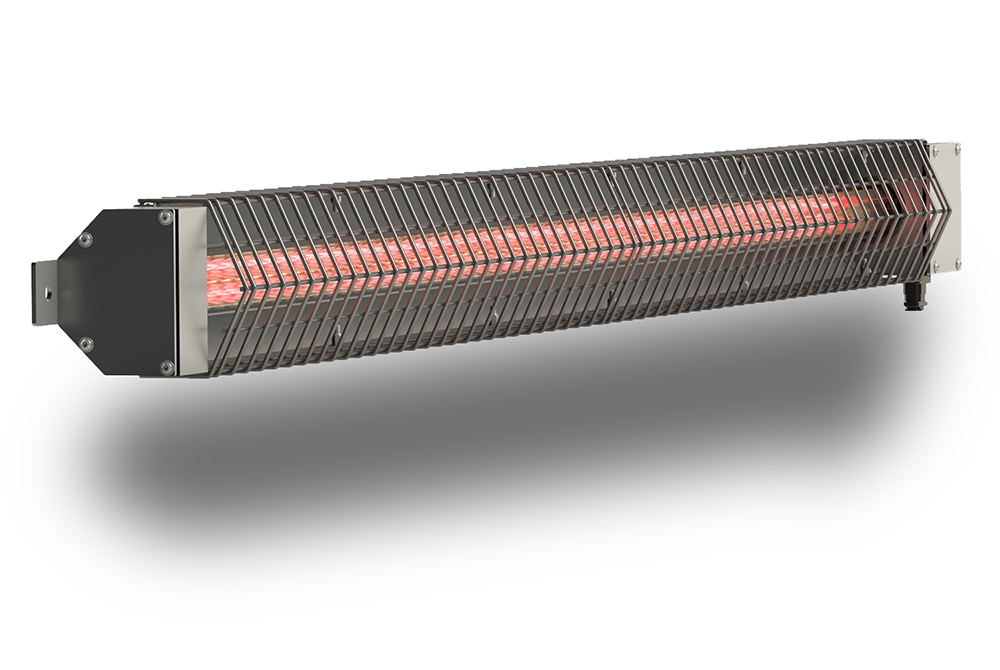

Infrared anti-icing were developed taking into account the constraints of the application, in particular to resist to shocks and vibrations. The system is well protected in a special housing made of stainless steel 316L, the emitters are protected with resisting quartz glass, the whole being dust-tight and waterproof.

Infrared anti-icing are available with a length from 610 mm to 2 440 mm.

Infrared-anti-icing are suitable for gas turbines, engines and other industrial applications.