Anti-icing nozzles

SAI patented anti-icing nozzles are used to allow an air intake system to operate even in very cold conditions without degrading the performance of the machine.

These nozzles are special silencers controlling the warm air (up to 500°C) distribution under high pressure to the air entry of turbo machines. They are positioned on a manifold structure allowing a homogeneous distribution of warm air inside the air inlet.

The anti-icing nozzles are located either in front of the filter pockets – preventing condensate ice formation – or after the air filters as bleed heating – preventing condensate ice formation on the compressor blades.

Patented and proven technology

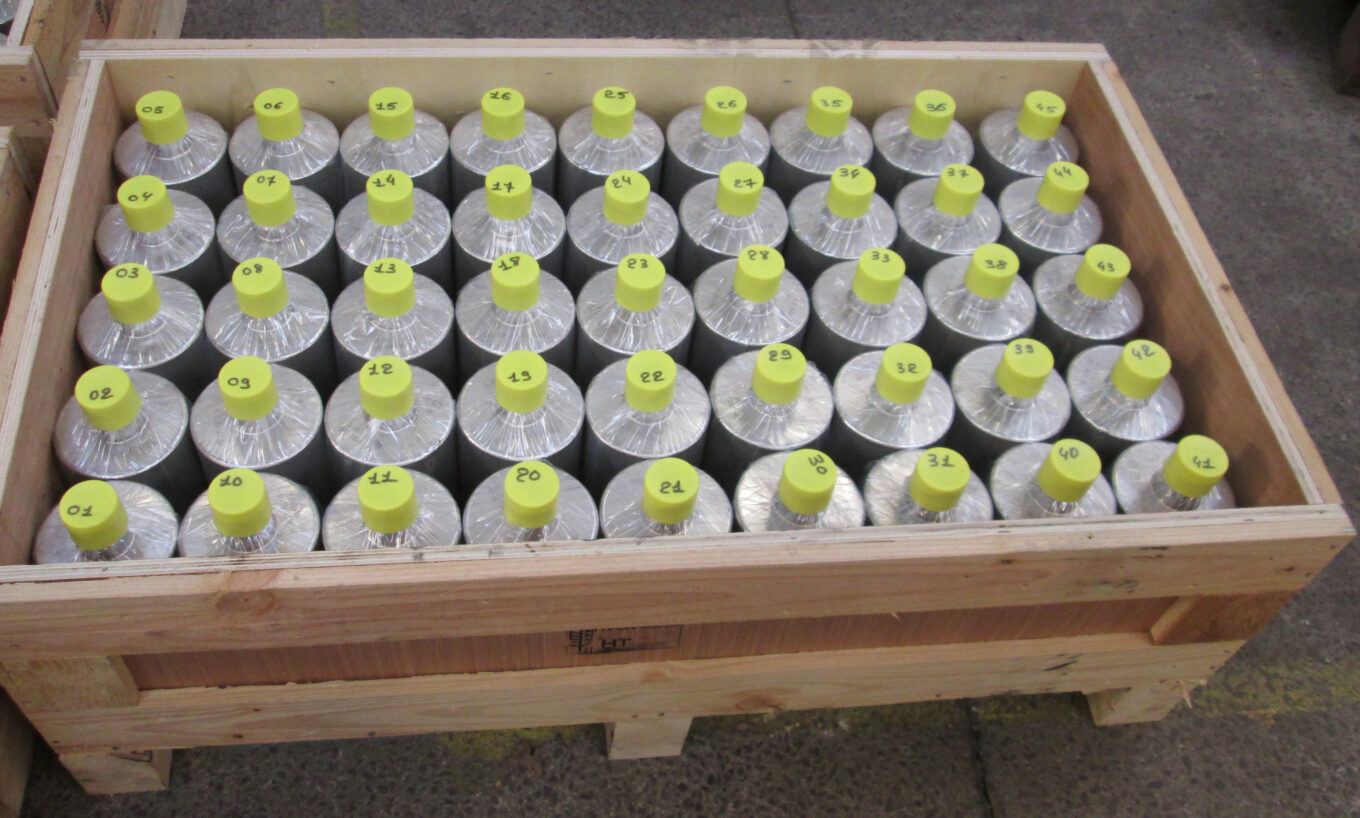

The design of SAI anti-icing nozzles is patented with 5 models available. The mechanical design allows up to 85 bars of pressure with a temperature of 540°C.

More than 60 000 SAI nozzles are in operation and give full satisfaction.

Options available for customization

All SAI nozzles are in full accordance with international construction codes such as CODAP, ASME VIII, … and fabricated in stainless steel (304L, 316L, 321..).

Inlet interface is DN32 (1’’1/4).

Options are available (inlet flange or butt weld or threaded …) to adapt the nozzles to existing installation.

SAI is able to design and provide a complete system including the manifold fabricated according to the international norms.

Acoustic performance guaranteed.

Hot air emission under high pressure is a natural source of noise to be under control.

Every nozzle installed on a manifold will contribute to noise attenuation down to a power level (SPwL) of 60dB(A) – Ref 10-12W calculated with the airflow rate, the temperature and the inlet pressure.