Noise reduction and turnkey project in a complex industrial environment

Engines: Acoustic enclosure

Scope of SAI supply: Noise reduction

Controlling noise emissions is a strategic challenge for industrial sites, particularly when located near residential areas. Aware of this issue a major player in the industry, entrusted SAI with the design and implementation of a turnkey acoustic solution for his site.

Combined acoustic and aerodynamic expertise serving performance

With its combined expertise in acoustic and aeraulics, SAI designed and implemented a custom-built solution to significantly reduce noise generated by the plant’s installations. Following a detailed acoustic assessment, the project included several key phases:

- Reinforcement of the “dust extraction workshop roof” building structure to support the load of the new system

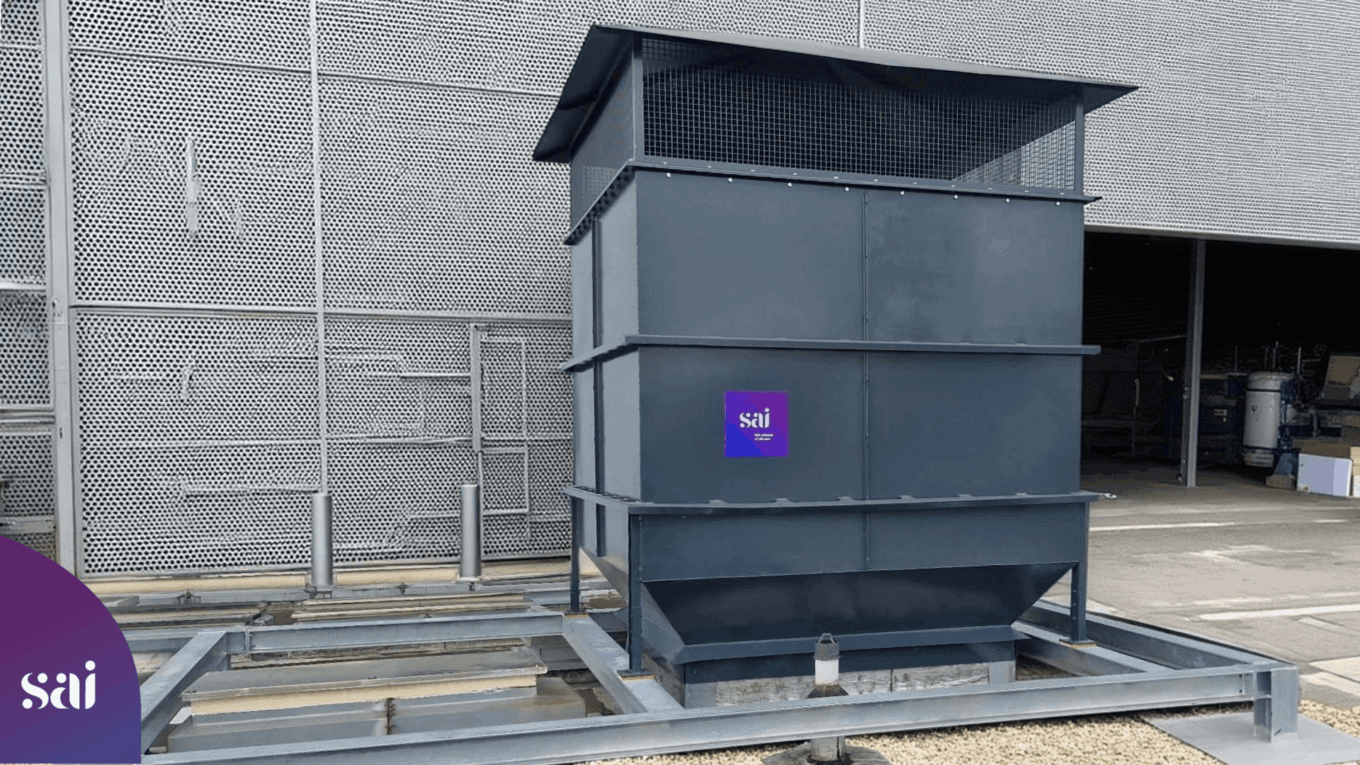

- Installation of an acoustic enclosure on the roof, mounted on a dedicated supporting frame

- Roof waterproofing works at the enclosure’s anchoring points

- Crane lifting and on-site installation in coordination with CL2R. The company dedicated to industrial services within the VIVERDE Group.

Reliable results fully aligned with your acoustic targets

The design of the acoustic silencer achieved a sound attenuation of -27 dB(A), fully in line with the target of -25 dB(A) — reducing the overall noise level from 100 dBA to 73 dBA. Post-installation measurements confirmed the accuracy of the theoretical performance predicted during the design phase.

From an aeraulic perspective, the solution ensures controlled pressure losses and optimal airflow conditions:

- Pressure drop: 87 Pa at 130,000 m³/h and 25.5°C

- Inter-baffle air velocity: 15 m/s

This performance ensures the reliability and continuity of the upstream ventilation systems while eliminating noise disturbance for the surrounding area.

A collaborative project within the VIVERDE Group

This project was carried out through the complementary expertise of the VIVERDE Group:

- SAI: design studies, engineering, and equipment supply

- CL2R: on-site supervision and installation

This was a real challenge for both companies, as the work had to be completed within a tight 6-day schedule.

Since the workshop is classified as an ATEX zone during operation, specific safety and coordination measures were implemented to enable the SAI and CL2R teams to deliver the turnkey solution within the scheduled 6-day shutdown window.

Towards more compliant and sustainable industrial environments

By delivering a turnkey solution tailored to industrial site’s specific requirements — particularly in reducing noise emissions to comply with regulatory standards — SAI reaffirms its ability to transform industrial acoustic challenges into reliable, measurable, and long-lasting solutions.

Are you facing noise issues on your industrial sites?

Our teams support you from acoustic studies through to equipment design, supply, and turnkey installation.

Contact-us to develop a solution tailored to your operational and regulatory challenges.